Details

Air Lock

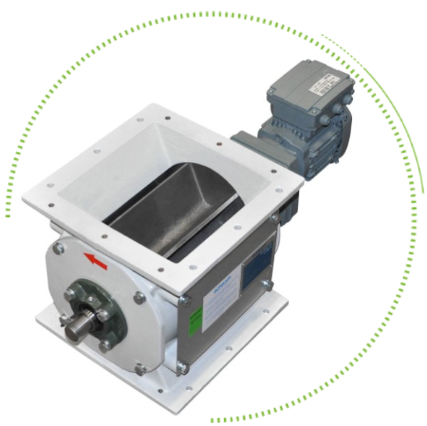

Air lock (rotary valve)

air locks are a type of rotary feeder and are often referred to simply as a Rotary Airlock or Rotary Valve. They provide feeding and metering functionality of a standard rotary feeder but their primary duty is to maintain pressure and provide an optimal airlock seal between different product conveying transitions, such as gravity to pneumatic conveying lines. An optimal airlock condition is essential to prevent air pressure loss in high pressure and high temperature conveying systems. airlock is also known as rotary valve, rotary feeder or airlock feeder. The main function of a rotary valve is to control flow of bulk solids from silo, mixer, cyclone or hopper under gravity, pressure and vacuum conditions.

High light features

• Provides perfect separation of air and dust particles in the cyclone due to its very precise fabrication

• Provides various drive possibilities, such as:

• By geared motor, direct flanged

• By geared motor, with coupling

• Minimum maintenance

• High efficiency