Details

Conditioner

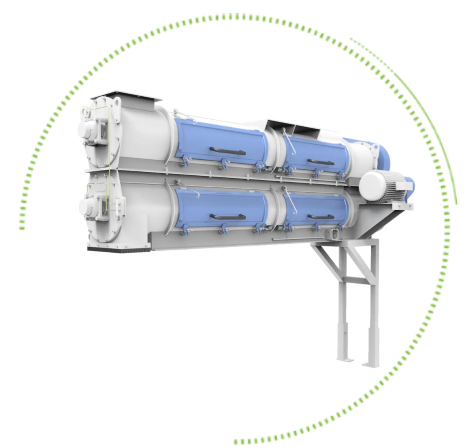

Feed Conditioner

Correct conditioning of a material is necessary in order to obtain a good pellet quality and an effective utilization of the pelleting or extrusion installation. Optimum conditioning results in the desired activation of natural binders by using heat, moisture, and time.

The conditioner allows up to one-minute treatment of the flour to obtain a highly durable pellet and increased productivity of the pellet mill.

It provides the pellet feed with excellent starch gelatinization and good pathogen abatement.

BENEFITS OF HEAT TREATMENT WITH STEAM IN FEED PELLETING

• The single-shaft conditioner significantly increases the productivity of the pellet mill.

• Increases the quality and durability of pellets.

• Increases the digestibility of the feed and the conversion factor in breeding.

• Increases the pellet shelf life.

• Removes salmonella and pathogens.

High light features

• Clean design and stainless steel construction

• Provides uniform feeding to the pellet mill or extruder

• feed conditioner works with direct steam, fed directly into the flour

• The quantity of product entering the conditioner is regulated by a screw feeder.

• It is possible to work between 40 °C and 85 °C, depending on the raw material to be treated and the presence of the tempolabile components;

treatment periods generally vary between 40 and 60 seconds.

• The blades are bolted and adjustable.

• Easy inspection and cleaning

• Controlled steam and liquid addition