Details

Hammer Mill

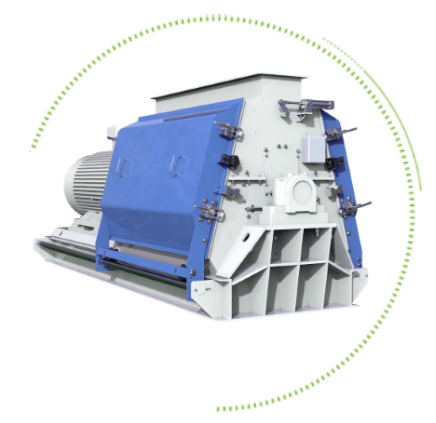

Hammer Mill

In the feed production system of livestock and poultry feed, hammer mill is used to crash raw material such as corn, barley, soybean etc. Rahavard company has develop a type of hammer mill that ensure the ability to work continuously. Strong steel body equipped with hardened hammers which are designed for long life working guarantee the achievement of different production capacity. Hardened steel hammers, superior quality bearings, housing design and precise motor drive systems connections are the main reasons of working of our hammer mills at the least level of vibration and increased production efficiency factors. (high production capacity, efficient energy consumption, less noise, etc.)

| Name | Model | Capacity | Power (kw) |

|---|---|---|---|

| Hammer Mill | RMH36 | 2 to 3 Ton/h | 30 |

| Hammer Mill | RMH48 | 3 to 5 Ton/h | 55 |

| Hammer Mill | RMH72 | 5 to 8 Ton/h | 75 |

| Hammer Mill | RMH96 | 8 to 12 Ton/h | 90 |

| Hammer Mill | RMH132 | 10 to 15 Ton/h | 132 |

High light features

• Durability

Our equipment is processed with high-standard steel, and the thickness of the body is higher than the same industry,

which greatly improves the service life.

• 3000 RPM Motor

This feed crushing machine with faster motor, improve the crashing efficiency and shorten the crashing time.

• Precision Control

Rotary feeding system is used to strictly control the feeding time to ensure the stability of production.

• High-standard Material and parts

Special heat-treated hammers, screen and bearing guarantee the high efficiency.

• Longer Service life

Rotor, passed the high-precision dynamic equilibrium experiment, works in slight vibration, thus has a long operating life.