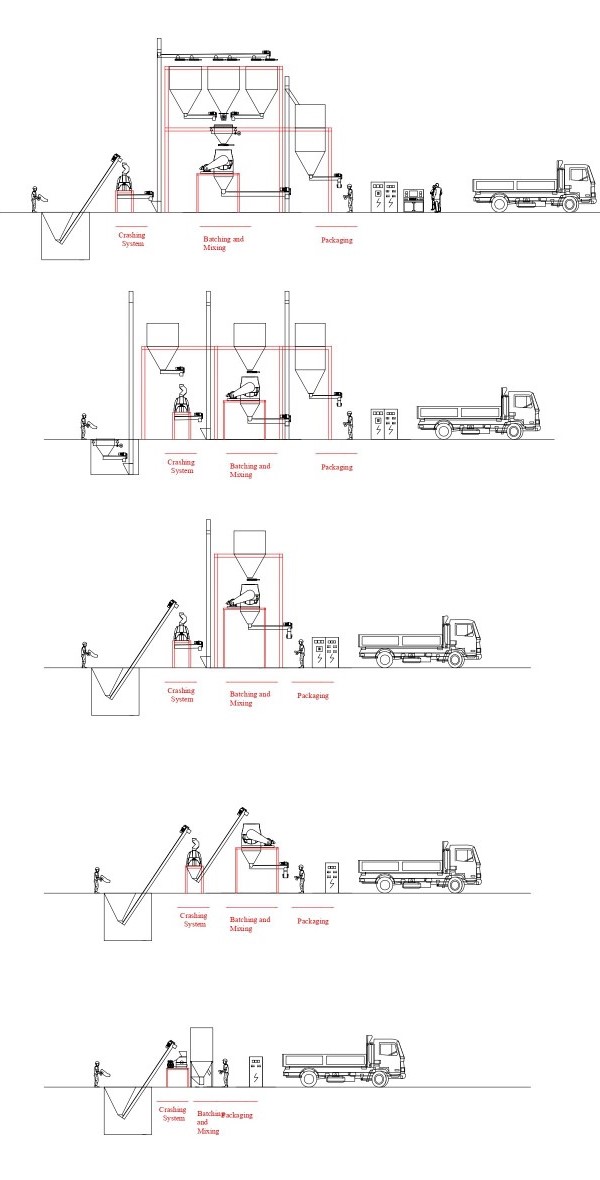

Production Lines

Mash Line

MASH FEED

Feed mash is the simplest solid feed form that can be manufactured.

It consists of grinding and mixing all raw materials into the correct proportions to meet nutritional

requirements of the insect. No additional heat- or compaction treatments are conducted on the feed; hence, energy expenditure to prepare the feed is low compared to pellets and extruded feed. Milling process method is one of the common processing methods in some countries due to its low cost and simplicity of work. This method will increase the productivity of nutrients because of breaking the outer protective coatings and increasing the accessibility for further digestion of the inner materials.

MASH FEED – livestock point of view

In ruminants, coarsely ground grains are preferred because fine grinding is not palatable for livestock and is mostly used in poultry and pig feed. Grinding is comparable to other methods when grain consumption is low. In addition to less digestion of starch, this method is less used for barley processing because of creating dust, which reduces the productivity potential of grain, but it is used in wheat and corn. On the other hand, the grinding method, because it makes the grain small and dusty, increases the rate of starch fermentation in the rumen and consequently increases the possibility of ruminal acidosis in ruminants. Another disadvantage of grinding grains is that due to the rapid passage of particles through the animal's rumen and its further digestion in the large intestine, it will also cause the possibility of colonic acidosis. Of course, with the digestive and functional comparisons of these methods in the studies, it is possible to better understand of importance of the choice of the most suitable method.

MASH FEED – poultry point of view

The grain ingredients for chicken feeds are first ground up into a powdered form, and then mixed together with

protein meal and health supplements. Mash feeds are suitable for chickens of all ages and sizes. They're used in

chick feeds and adult feeds, and can be fed to full size chickens and bantams. It is the least processed,

and often least expensive form of complete feed. Despite the attractive price tag, mash comes with it's share of unfavorable effects.

1.Feed Dust: The ground grains in this feed produce the most grain dust of any form of feed. Feed dust is a waste of feed the chickens cannot eat, and also poses a respiratory hazard to chickens and humans alike.

2. Feed Separation: Mash quality is evaluated by its uniformity in mash size: so the cheaper the grain, the larger the disparity in grain sizes, and the more feed separation occurs. Feed separation allows chickens to peck through the feed, selectively eating the larger, higher calorie ingredients over the smaller more nutritionally dense ingredients.

3. Feed Waste: While picking through the separated feeds, they use their beak or feet to scatter the mash from the feeder to the ground for a better look at what's available to them. Once it hits the ground much of this feed is never eaten. It is too small to find in the dirt, and becomes stale or contaminated with chicken feces.

4. More Rodents: The mess of feed on the ground attracts mice and rats, and increases the chance of diseases introduced by rodents, and illnesses associated with moldy feeds.