Details

Micronizer

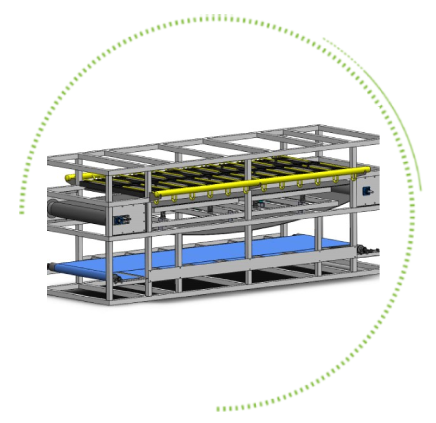

Micronizer

The Nitrogen protection jet mill system uses Nitrogen gas as media for pneumatic mining to perform dry-process superfine pulverization. The jet mill system mainly consists of compressor, air storage tank, material storage tank, jet mill, cyclone separator, collector and automatic controller. When the system is activated,nitrogen gas will be released into the system to drive the air out till the whole system reaches the numerical value fixed by the oxygen detector. Then the system will automatically start the material feeding device to feed the materials evenly into the milling chamber of the jet mill. The compressed nitrogen gas is injected at a high speed into the milling chamber by means of special ultrasonic nozzle.Therefore, the materials will be ground by being accelerated, impacted and collided repeatedly in the midst Of ultrasonic injection flow. The ground materials will be brought together with upflow to the grading chamber. They cannot enter the grading wheel and will be swirled back into the milling chamber for further milling. The thinner grains will enter the grading wheel and be blasted to cyclone separator and collector whereas the nitrogen gas will return to the compressor, through Which it will be compressed for recycling.

| Name | Model | Capacity | Power (kw) |

|---|---|---|---|

| Micronizer flaker | RMS 12 | 1 ton | call |

| Micronizer flaker | RMS 24 | 3 ton | call |

| Micronizer flaker | RMS 36 | 5 ton | call |

High light features

You can adjust the output size by adjusting the speed of the grading wheel.

There is no sieve inside the chamber. Easier to use than the pulverizers with a sieve.

Continuous working is suitable for industrial production.

There is no dust flying during production.

We use stainless steel to produce micro mill, which assures final products healthy and clean.

We can change the position of the connecting pipes according to the space of customer's workshop.

Can be equipped with water cooling system to cool down the temperature inside the crushing chamber to keep working continuously.