Details

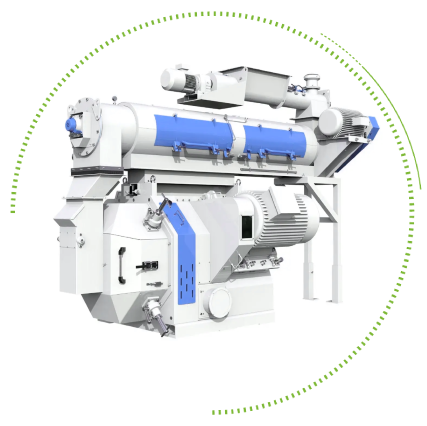

Belt Driven

Pellets with a belt-driven power transmission system

according to the optimal design and precision in the manufacturing process and the use of the best consumable parts, long life ease of use and uniform and economical production for this machine are guaranteed. Protection systems such as shear pin and control micro switches will prevent failure due to Any sudden increase in workload. The power transmission system in this type of pellet machine is a belt type that transfers the power of the two electromotor of the machine to the main shaft. The optimal design of the conditioner for adding steam or molasses achieves the best percentage of moisture and temperature in the pelleted feed, which assure high quality final product. all parts which are in contact with produced feed, including the main door and all conditioners parts are made of stainless steel to avoid any undesirable corrosion.

| Name | Model | Capacity | Power(Kw) |

|---|---|---|---|

| Pellet Mill | RBP350 | 2 to 3 Ton/h | 2*30 |

| Pellet Mill | RBP450 | 4 to7 Ton/h | 2*55 |

| Pellet Mill | RBP580 | 8 to 12 Ton/h | 2*90 |

| Pellet Mill | RBP650 | 12to17 Ton/h | 2*110 |

High light features

• The Feeder and conditioner:

the feeding chute adopt stainless steel material for structural durability.

• Feeding system:

The variable frequency feeding system which is convenient for speed adjustment and uniform feeding.

• Security:

strong permanent magnet and overload protection device such as a safety pin and electrical protection system.

• application:

easy operation, high output, long service life, less consumption, easy to use and maintenance