Production Lines

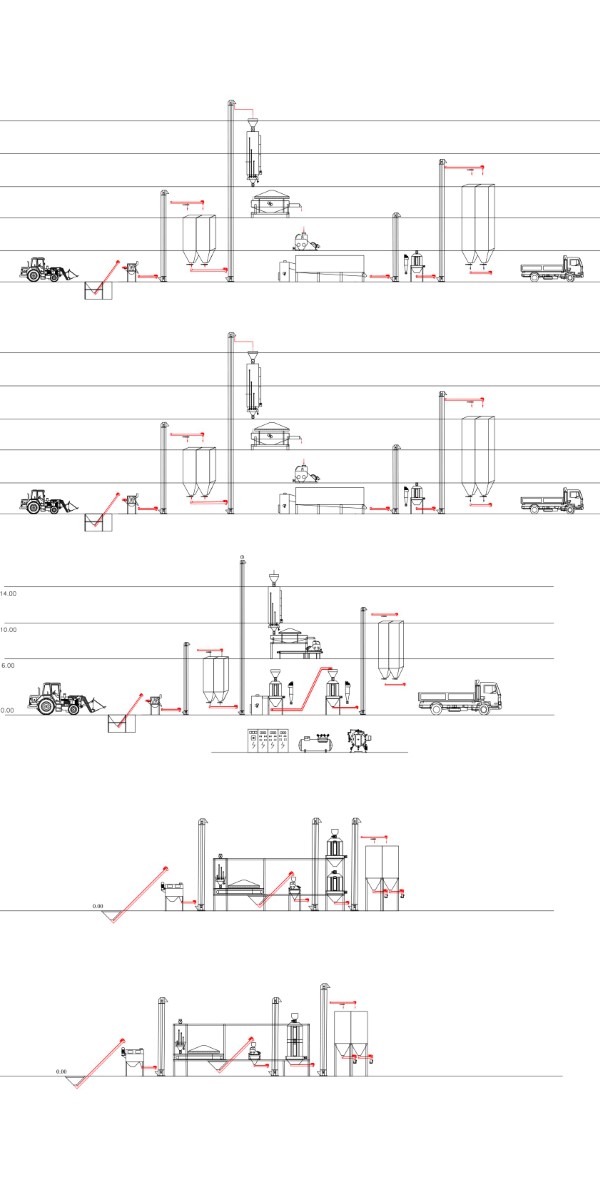

Flake Line

steam flake line

Cereal grains, which are known as starch-rich grains, are completely different from each other in terms of physical and chemical structure, and thus have different levels of digestibility in ruminants and monogastrics. Barley and corn are the most important grains used by livestock, poultry and aquatic animals in Iran. (Average annual amount) In terms of protein-starch matrix, these seeds have a resistant structure against microbial and animal digestive.

enzymes. In this sense, during the studies and application of animal nutrition science, there has been an attempt to change this structure by using physical and thermal methods. In physical and thermal methods, moistened grains have been exposed to heat sources at different times, which, while disintegrating the protein-starch matrix, increases the gelatinization potential of starch and, as a result, increases its digestibility per unit of time.

During nutritional studies, all animal nutrition experts believe that seed processing will bring many benefits such as the following in the livestock and poultry industry. These benefits include:

Continue the description

• Improvement of feed conversion ratiobr

• Improve feed intake

• Improving growth, milk and meat production

• Improving the quality of carcass and milk

• Reducing the excretion of undigested nutrients

• Reducing the cost of wasting nutrients in storage conditions

• Reducing the daily fees of milk and meat producing units

• Improvement in reproduction rate

• Improving general and metabolic health of ruminants

• Improvement in feed consumption under stressful conditions, such as heat and environmental stress

• Improve ration adjustment

• Improving the management of feed consumption

• Improve stool conditions

• Improving ruminal and small intestinal digestion and reducing fermentation in the large intestine in livestock

• Subtle improvement of conversion in poultry

Based on the above, increasing the nutritional value is perhaps the most important reason for the physical processing of cereal grains. Nutritional value is a conventional term in animal nutrition. But this word includes different dimensions such as the concentration of nutrients in the animal feed, and the ratio of production to consumption of nutrients. Therefore, it seems that the nutritional value of the feed depends on its chemical composition and physical form when used by the animal. These two features are important since they affect the rate of appetite and feed intake, digestibility and common conditions between the alimentary canal and feed. Therefore, in order for a feed to be able to show its characteristics in production indicators, in addition to optimal digestion in the animal digestion system, it must also prepare the conditions for optimal absorption and metabolism of nutrients. In such a situation, the economic effect of feed emerges in terms of reducing costs and increasing the profit of the production unit. Therefore, in ruminants, the most appropriate physical method should have features that, while not reducing the PH of the rumen fluid, provide the conditions for post-ruminal digestion and increased absorption. So, the following conditions must be taken into account in any physical method.

• Particle size at the time of animal use

• Thermal processing and its conditions

• Storage conditions and how to use