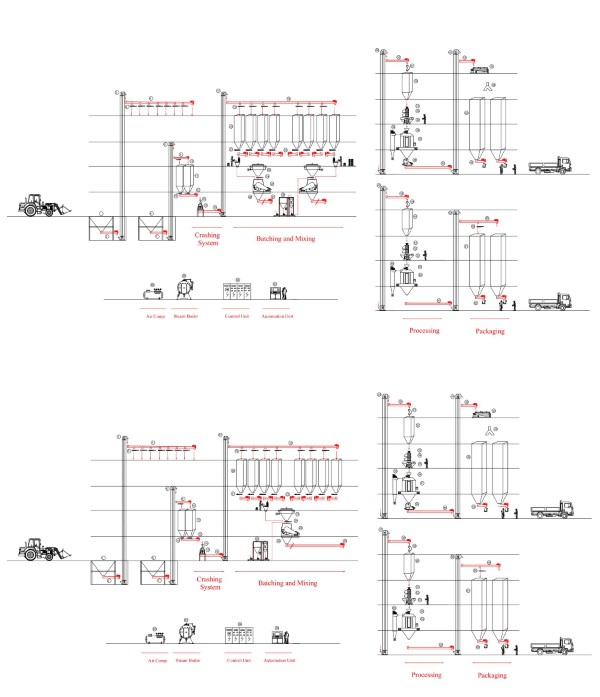

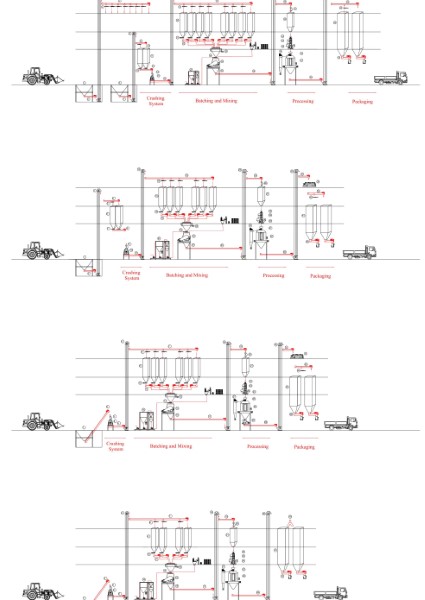

Production Lines

pellet Line

ANIMAL FEED PELLETING

Compound feeds are mostly employed in the animal feed business as pellet feed and mash feed. In recent years,

due to its simple transportation and good economic efficiency, animal feed pellets have become an increasingly

popular choice among animal feed investors.

THE HISTORY OF ANIMAL FEED PELLETING

For centuries people allowed their pigs and chickens to forage and occasionally tossed them some food scraps.

The industrial revolution changed that.

Farmers now needed horsepower. Horses that supplied power needed high energy feeds.

Horses that provided transportation needed feeding stations along the way. Horses that went to war had to carry their feed with them.

The British developed the first compound feed as transportable nourishment for war horses.

The feed, resembling a large baked biscuit, was a combination of meal from oat, peas, rye, flax, wheat or maize. According to feeding experiments done by the Prussian army, 1.5 kg (3 3/8 lb) of this compound horse feed could substitute for 5 kg (11 pounds) of oats.

Concentration of food processing, particularly large flour mills, created a new environmental problem:

These mills (conveniently built close to water) began dumping waste into rivers and streams.

As tons of wheat midds fouled the waters, the government intervened and prohibited dumping by law. The midds had nutritional value for animals but did not flow well, had low bulk density, dusty texture and, therefore, were not pleasant to eat. Whey generated by cheese production, and meat and bone meal from the packing plants were equally problematic.

In 1928, the needs for efficient animal feeds, and use of industrial food wastes were both brilliantly

satisfied when Purina began pelleting flour mill waste. Wheat midds were mixed with animal by-products or

soya cake, plus ground corn and minerals, and compressed into convenient pellets. The obvious advantages were:

• Less dust

• Increased bulk density

• Improved flow ability

• Improved palatability

• Reduced feed wastage

• Increased consumption rate

• Less energy expended in consumption

• Dense minerals did not segregate out

WHAT IS PELLETING?

Pelleting is the process of converting finely ground mash feed into dense, free flowing pellets or capsules.

When we say “pelleting”, we refer to the process of compressing materials through a die to form a cylindrical

shape with a length that is generally 2–4 times its diameter.

Continue the description