Ring Die

The steel we use is high-carbon and high-chromium steel, which has the advantages of wear resistance, corrosion resistance, and high strength. Ring dies are manufactured with advanced special purpose gun drills to ensure precise assembly dimensions and arrangement of die holes. The opening ratio and compression ratio are supported by rich design experience, which can meet the requirements of different raw materials and different granules for ring die, and improve the quality and efficiency of granulation.

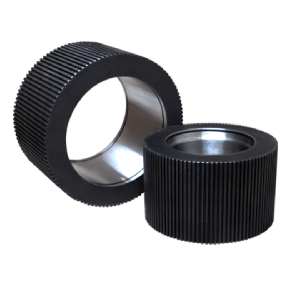

Roller Shell

For the roller shell, automated high-precision advanced instruments are used to ensure a uniform tooth profile. As a manufacturer, we can control the quality of the roller shells during the entire manufacturing process, from raw materials to any subsequent steps, and all roller shells being inspected and run before delivery. It is recommended that the new press roll be used with the new ring die.

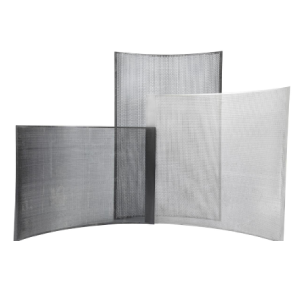

Hammer Mill Sieve

The higher the opening ratio of the sieves, the greater the production capacity of the hammer mill. The larger the effective use area of the sieves, the higher the efficiency. The opening size of the sieves depends on the required particle size, and the sieves with the largest aperture should be selected as much as possible according to the strength of the sieves.

Hammer Mill Blades

Specific design of our blades ensure extending the useful life of your hammers & wear parts. Another key success factor of our blades is Applying the hard alloy only where it is necessary to meet your product's wear needs. We keep a large inventory of hammers in stock.

Pellet Mill Bearing

Pellet machine bearings are generally installed on the rotating parts of the machine, such as spindles, rollers, etc. Their main function is to support and reduce friction between machine parts so that the machine can run smoothly. In the pellet machine, the bearings need to withstand extreme conditions such as high-speed rotation, high temperature and high load, so it is very important to choose bearings with wear resistance, high temperature resistance and high strength.

Pellet Mill Eccentric Shaft

Roller shaft also called eccentric shaft is a part for roller assembly on ring die pellet mill, we supply different kinds of roller shafts for ring die pellet mill and flat die pellet mill. We have a roller shaft for biomass fuel pellets/wood pellets and animal feed pellets.

Pellet Mill Adjustment Wheel

The Pellet Mill Adjustment Wheel is an important accessory for the wood pellet machine, used to adjust the pressure of the pellet machine. Pellet Mill Adjustment Wheels are typically made of steel for high strength and wear resistance. The diameter and thickness of the wheels need to be selected according to the specific model of the pellet machine.

Recent Post

Useful Links

Our Slogan

Quality Products Trusted Performance